Efficiency

How to Measure Sewing Line Efficiency?

Sewing Line Efficiency

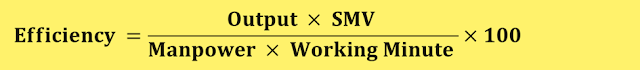

In the garments industry, efficiency is the ratio of produced minutes to spent

minutes multiplied by 100. The formula to calculate Operator Efficiency, Sewing

Line efficiency, Sewing Floor or Unit Efficiency and entire Factory Efficiency

are the same. Just have to change some value to calculate the specific type of

efficiency. In this article, we will learn how to calculate a Sewing Line

Efficiency.

|

| Figure: Sewing Line Efficiency |

Sewing Line Efficiency Calculation

The common formula to calculate

efficiency is-

Here,

Output = Number of garments pieces

produced in the line

SMV =

Standard Minute Value of the garment

Manpower = Number or the worker worked (Operator + Helper + ironman)

Working minute = Total minute work to produce the

garments.

Example:

A sewing line output is 1600 pcs in 9 hours. The operator was 32, the helper was 4 and the ironman was 2 and the garment SMV is 7.32. What is the efficiency of the sewing

line?

Here,

Output = 1600 pcs

SMV =

7.32

Manpower = 32+4+2 =

38

Working minute = 9 hours = 9 × 60 = 540 minutes

If

we put all the value in the efficiency formula we will find the efficiency of

that sewing line.

So, Sewing Line Efficiency = [(1600 × 7.32)/(38 × 540)] × 100 = 57.08%

Post a Comment

0 Comments